Comprehensive Guide to Welded Wire Mesh Rolls in Construction

Release Time:

Apr 17,2025

Welded wire mesh rolls are a versatile and highly effective solution used extensively in the construction industry. Composed of intersecting wire strands that are welded together, these rolls provide a robust framework suitable for various applications. Understanding the properties of welded wire mesh rolls can significantly enhance their utility in construction projects. One of the primary benefi

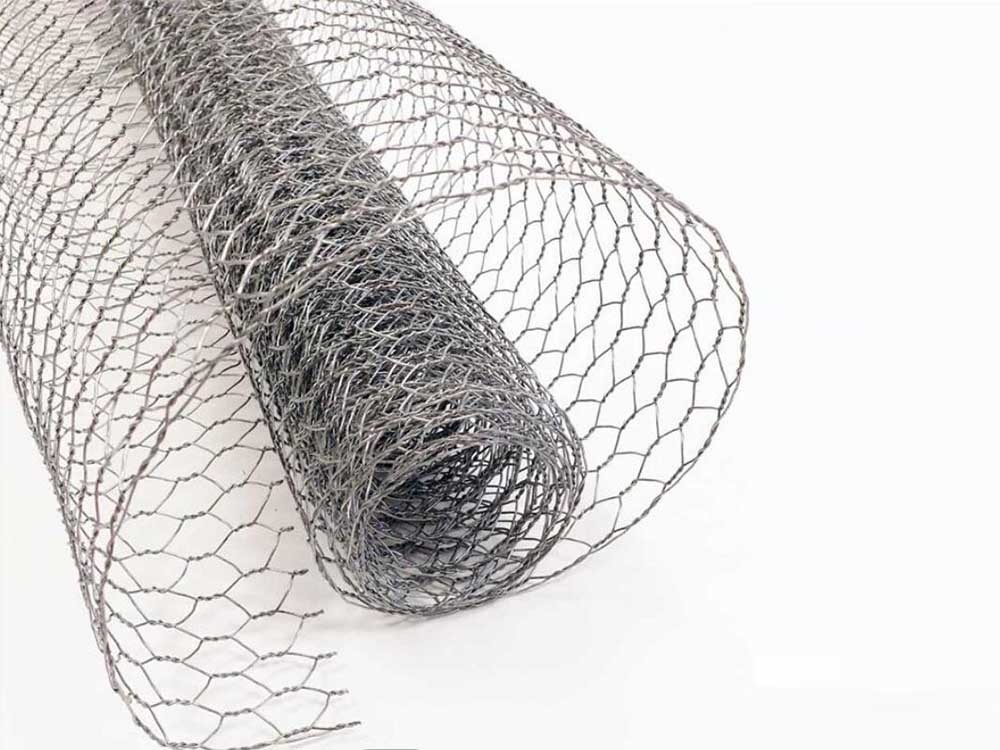

Welded wire mesh rolls are a versatile and highly effective solution used extensively in the construction industry. Composed of intersecting wire strands that are welded together, these rolls provide a robust framework suitable for various applications. Understanding the properties of welded wire mesh rolls can significantly enhance their utility in construction projects.

One of the primary benefits of using welded wire mesh rolls is their structural integrity. The welding process ensures that the wires are securely bonded at each intersection, offering superior strength compared to other types of wire mesh. This makes welded wire mesh an ideal choice for reinforcing concrete structures, providing additional support and stability. It is commonly utilized in foundations, slabs, walls, and even in road and bridge construction.

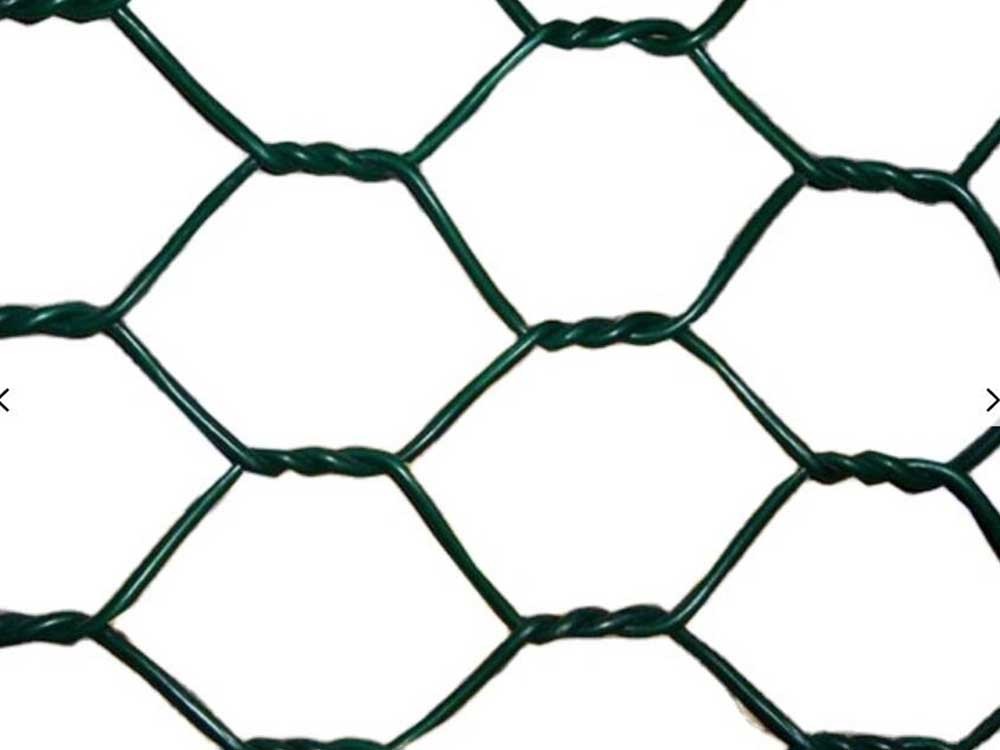

In addition to structural reinforcement, welded wire mesh rolls are also used for fencing and security applications. The high tensile strength of the welded mesh makes it difficult to break or cut, making it a preferred choice for enclosing properties, gardens, and construction sites. The uniform spacing of the mesh openings also allows for visibility while ensuring safety and security.

Welded wire mesh rolls are available in various sizes, wire diameters, and mesh patterns, making them adaptable to different project requirements. When selecting a welded wire mesh roll, it is essential to consider factors such as the intended application, load-bearing requirements, and environmental conditions. For instance, galvanized or stainless steel options provide increased resistance to corrosion, making them suitable for outdoor or harsh environments.

Another critical aspect to consider is the ease of installation. Welded wire mesh rolls can be easily cut, bent, or shaped to fit specific project needs. This flexibility allows contractors to efficiently incorporate them into a variety of designs and structures, ultimately saving time and labor costs.

When working with welded wire mesh rolls, it is important to follow best practices to ensure optimal performance. Proper handling and storage are crucial to prevent damage to the mesh during transportation or on-site. Additionally, ensuring that the mesh is correctly placed within the concrete mix will maximize its reinforcing capabilities, enhancing the overall strength and longevity of the structure.

In conclusion, welded wire mesh rolls represent a reliable and versatile option for construction professionals. By understanding their benefits and applications, one can make informed decisions that enhance the quality and durability of construction projects. Whether used for reinforcement, fencing, or decorative purposes, incorporating welded wire mesh rolls can lead to successful outcomes in the building industry.

One of the primary benefits of using welded wire mesh rolls is their structural integrity. The welding process ensures that the wires are securely bonded at each intersection, offering superior strength compared to other types of wire mesh. This makes welded wire mesh an ideal choice for reinforcing concrete structures, providing additional support and stability. It is commonly utilized in foundations, slabs, walls, and even in road and bridge construction.

In addition to structural reinforcement, welded wire mesh rolls are also used for fencing and security applications. The high tensile strength of the welded mesh makes it difficult to break or cut, making it a preferred choice for enclosing properties, gardens, and construction sites. The uniform spacing of the mesh openings also allows for visibility while ensuring safety and security.

Welded wire mesh rolls are available in various sizes, wire diameters, and mesh patterns, making them adaptable to different project requirements. When selecting a welded wire mesh roll, it is essential to consider factors such as the intended application, load-bearing requirements, and environmental conditions. For instance, galvanized or stainless steel options provide increased resistance to corrosion, making them suitable for outdoor or harsh environments.

Another critical aspect to consider is the ease of installation. Welded wire mesh rolls can be easily cut, bent, or shaped to fit specific project needs. This flexibility allows contractors to efficiently incorporate them into a variety of designs and structures, ultimately saving time and labor costs.

When working with welded wire mesh rolls, it is important to follow best practices to ensure optimal performance. Proper handling and storage are crucial to prevent damage to the mesh during transportation or on-site. Additionally, ensuring that the mesh is correctly placed within the concrete mix will maximize its reinforcing capabilities, enhancing the overall strength and longevity of the structure.

In conclusion, welded wire mesh rolls represent a reliable and versatile option for construction professionals. By understanding their benefits and applications, one can make informed decisions that enhance the quality and durability of construction projects. Whether used for reinforcement, fencing, or decorative purposes, incorporating welded wire mesh rolls can lead to successful outcomes in the building industry.

Keywords:

More information