How Hexagonal Wire Mesh Enhances Structural Integrity: A Comprehensive Guide

Release Time:

Jun 01,2025

How Hexagonal Wire Mesh Enhances Structural Integrity Table of Contents 1. Introduction to Hexagonal Wire Mesh 2. What is Hexagonal Wire Mesh? 3. The Importance of Structural Integrity in Construction 4. Benefits of Using Hexagonal Wire Mesh 5. Applications of Hexagonal Wire Mesh in Various Industries 6. Installation Techniques for Optimal Performance 7. Maintenance and Durabili

How Hexagonal Wire Mesh Enhances Structural Integrity

Table of Contents

- 1. Introduction to Hexagonal Wire Mesh

- 2. What is Hexagonal Wire Mesh?

- 3. The Importance of Structural Integrity in Construction

- 4. Benefits of Using Hexagonal Wire Mesh

- 5. Applications of Hexagonal Wire Mesh in Various Industries

- 6. Installation Techniques for Optimal Performance

- 7. Maintenance and Durability: Ensuring Longevity

- 8. Case Studies: Real-World Applications and Success Stories

- 9. Conclusion

- 10. FAQs

1. Introduction to Hexagonal Wire Mesh

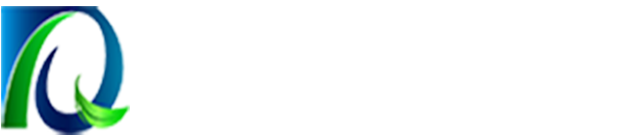

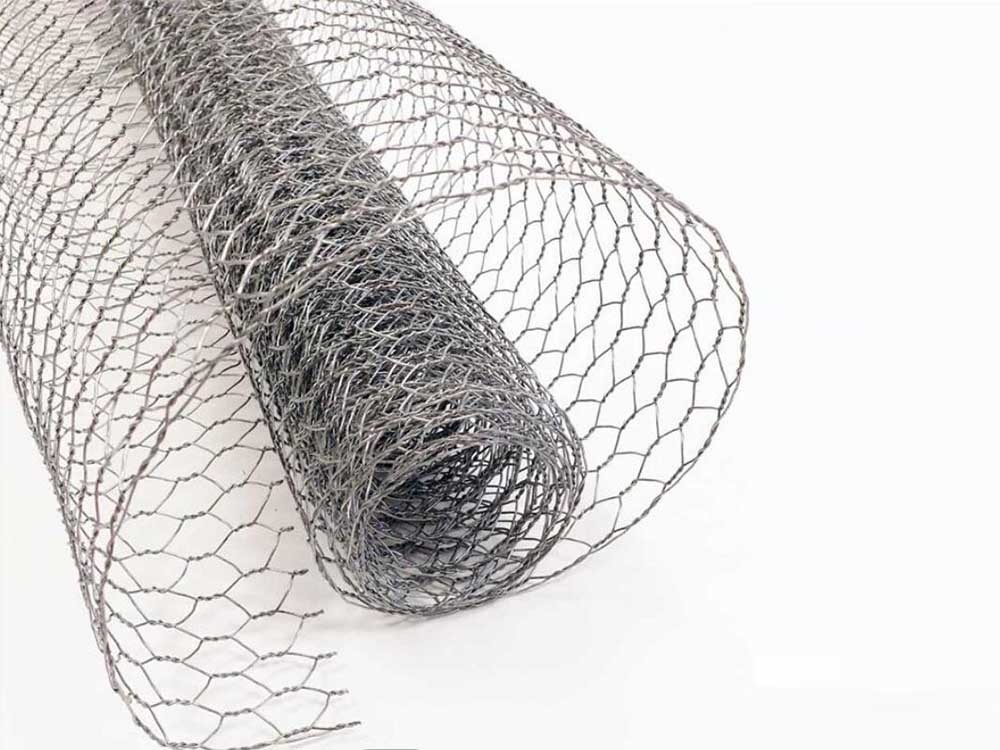

Hexagonal wire mesh, also known as hex mesh or hexagonal mesh, is a versatile construction material that has gained significant popularity due to its unique properties and applications. This type of mesh, characterized by its hexagon-shaped openings, provides outstanding strength and flexibility, making it an excellent choice for various structural and decorative applications. In this article, we explore how hexagonal wire mesh can enhance structural integrity, ensuring safe and durable constructions.

2. What is Hexagonal Wire Mesh?

Hexagonal wire mesh is made from high-quality steel or metal wires that are woven together to form a mesh with hexagonal openings. This design allows for even distribution of load and enhances the overall strength of the material. Hexagonal wire mesh comes in various gauge sizes, making it adaptable for different applications, whether in construction, agriculture, or industrial settings. Its inherent flexibility allows it to be used in dynamic environments where structural integrity is paramount.

3. The Importance of Structural Integrity in Construction

Structural integrity refers to the ability of a structure to withstand its intended load without experiencing failure due to deformation or collapse. Ensuring structural integrity is crucial in construction as it directly impacts safety, longevity, and durability. A compromised structure can lead to disastrous consequences, including injuries, financial loss, and legal implications. Hence, materials that enhance structural integrity, like hexagonal wire mesh, are essential in modern construction practices.

4. Benefits of Using Hexagonal Wire Mesh

The advantages of incorporating hexagonal wire mesh in construction and various industries are numerous:

4.1 Enhanced Load Distribution

Hexagonal wire mesh distributes loads evenly across its structure, reducing the chance of localized stress points that could lead to failure.

4.2 Increased Flexibility

This type of mesh is flexible and can conform to different shapes and dimensions, making it suitable for a wide range of applications.

4.3 Corrosion Resistance

Hexagonal wire mesh is often coated with materials that provide excellent resistance against rust and corrosion, enhancing its lifespan, especially in harsh environments.

4.4 Cost-Effective Solution

Compared to other materials, hexagonal wire mesh is relatively affordable and can be produced in large quantities, making it a cost-effective option for construction projects.

4.5 Easy Installation

The lightweight nature of hexagonal wire mesh allows for straightforward handling and installation, reducing labor costs and time on-site.

5. Applications of Hexagonal Wire Mesh in Various Industries

Hexagonal wire mesh finds applications across multiple industries due to its strength and versatility. Here are some noteworthy examples:

5.1 Construction

In the construction industry, hexagonal wire mesh is employed for reinforcing concrete structures, providing additional support to walls, floors, and roofs. It also enhances the durability of retaining walls and other earthworks.

5.2 Landscaping and Gardening

Hexagonal wire mesh is used in landscaping projects to create garden borders, trellises, and fencing. Its flexibility allows it to be shaped into various designs while providing a stable structure for plants to climb.

5.3 Agriculture

In agriculture, hexagonal wire mesh serves as fencing for livestock and protection for crops. Its robust nature ensures that it can withstand harsh weather conditions and protect against wildlife.

5.4 Industrial Applications

Various industrial settings utilize hexagonal wire mesh for filtration, separation processes, and safety barriers. Its ability to withstand heavy loads makes it suitable for protective frames and storage enclosures.

5.5 Decorative Uses

Beyond functional applications, hexagonal wire mesh is also used in interior design and architecture as decorative elements, providing a unique aesthetic appeal to spaces.

6. Installation Techniques for Optimal Performance

When installing hexagonal wire mesh, following proper techniques is vital to ensure optimal performance and durability.

6.1 Planning and Measurement

Before installation, careful planning and accurate measurements are necessary. This process ensures that the hexagonal wire mesh fits correctly within the intended space.

6.2 Ground Preparation

For construction applications, preparing the ground is essential. The area should be cleared, leveled, and compacted to provide a stable base for the wire mesh.

6.3 Securing the Mesh

Hexagonal wire mesh can be secured using various methods, including staples, nails, or tension wire. The chosen method should depend on the application and the load it will bear.

6.4 Regular Inspections

After installation, it’s crucial to conduct regular inspections to identify any wear or damage. Addressing issues promptly will prolong the lifespan of the mesh and ensure its structural integrity.

7. Maintenance and Durability: Ensuring Longevity

Maintaining hexagonal wire mesh is vital for ensuring its durability and effectiveness over time. Here are key maintenance tips:

7.1 Regular Cleaning

Keeping the mesh clean prevents the buildup of debris that could lead to corrosion or weaken its structure. A simple rinse with water or a mild detergent can suffice.

7.2 Inspecting for Damage

Routine inspections to check for rust, deformation, or other types of damage are essential. Early detection can facilitate repairs and avoid costly replacements.

7.3 Protective Coatings

Applying protective coatings can enhance the mesh's resistance to corrosion and weathering, further extending its lifespan.

7.4 Avoiding Overloading

To maintain structural integrity, it is essential not to exceed the recommended load capacities of hexagonal wire mesh installations.

8. Case Studies: Real-World Applications and Success Stories

Analyzing real-world applications of hexagonal wire mesh provides insights into its effectiveness and versatility:

8.1 Urban Construction Project

In a recent urban construction project, hexagonal wire mesh was utilized in the reinforcement of concrete walls. The application resulted in increased stability and reduced cracking over time.

8.2 Agricultural Fencing

A local farm used hexagonal wire mesh for fencing around livestock areas. The mesh proved effective in keeping animals secure while allowing for good visibility and air circulation.

8.3 Landscape Design

A landscape architect incorporated hexagonal wire mesh in a garden trellis design. The mesh provided structural support for climbing plants and added a modern aesthetic to the outdoor space.

9. Conclusion

Hexagonal wire mesh serves as a crucial element in enhancing structural integrity across various applications. Its unique properties, including flexibility, load distribution, and corrosion resistance, make it an ideal choice for construction, agriculture, and decorative uses. By understanding the benefits and proper installation techniques, stakeholders in the construction industry can significantly improve the durability and reliability of their projects. Embracing hexagonal wire mesh is not just a trend; it’s a step towards safer, more resilient construction practices.

10. FAQs

What is the primary benefit of using hexagonal wire mesh in construction?

The primary benefit is its ability to enhance structural integrity by distributing loads evenly and providing robust reinforcement.

Can hexagonal wire mesh be used in harsh environments?

Yes, when coated appropriately, hexagonal wire mesh offers excellent resistance to corrosion and can withstand harsh environmental conditions.

How do I install hexagonal wire mesh?

Installation involves careful planning, ground preparation, securing the mesh using appropriate methods, and conducting regular inspections after installation.

Is hexagonal wire mesh cost-effective?

Yes, hexagonal wire mesh is generally affordable and cost-effective, especially when considering its durability and the savings from reduced maintenance needs.

What maintenance is required for hexagonal wire mesh?

Regular cleaning, inspections for damage, applying protective coatings, and avoiding overloading are essential for maintaining hexagonal wire mesh.

Keywords:

More information